Companies today need to make high-quality products. Traditional ways of checking for defects are no longer good enough. AI-Based Smart Quality Inspection is a new way to find defects and ensure quality. With AI, manufacturers can automate the inspection process. This makes it more accurate and faster. This blog post explains how AI-based smart quality inspection helps find defects better. It talks about the technology, the benefits, real-world uses, and the future of quality inspection in manufacturing.

The Advent of Artificial Intelligence in Quality Inspection

Using AI for quality inspection is a big change in manufacturing. It’s different from the old ways of checking by hand. People doing inspections can make mistakes. They can get tired or see things differently. AI doesn’t have these problems. AI systems can keep working without getting tired or inconsistent. AI brings more accuracy, speed, and consistency than people can. AI doesn’t have the limits that affect human inspectors.

Quality inspection systems use smart computer programs to detect defects. They learn from huge amounts of data. This helps them spot flaws more accurately than humans can. The system keeps learning as it gets more data. It gets better at finding defects over time. Using artificial intelligence (AI) doesn’t just improve old inspection methods. It completely changes how inspections are done. This promises a future with more reliable and flexible quality control.

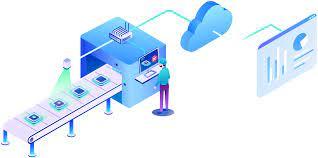

AI-based inspection systems combine machine learning, computer vision, and advanced sensors. Together, these technologies let the system “see” and “understand” products like a human inspector would. But the system works faster and more precisely than humans. This is a major shift in manufacturing. It allows for unprecedented quality and efficiency in production.

Key Technologies Powering AI-Based Smart Quality Inspection

AI-based quality inspection systems use machine learning, computer vision, and sensor technology. Machine learning programs are like the system’s brain. They study patterns in huge datasets to identify defects. Deep learning models are especially good at this. The more data they get, the better they become at finding even tiny flaws. They continuously improve over time.

Computer vision helps systems see things clearly. It uses methods like segmenting images, detecting objects, and classifying them. With computer vision, systems can carefully inspect products in real-time. They can spot defects that humans might miss. This ability is crucial for meeting quality standards.

Advanced sensors provide the high-quality data needed for accurate analysis. These include high-definition cameras and sophisticated scanning devices. They capture detailed images and measure products during manufacturing. This rich data allows machine learning algorithms and computer vision systems to work effectively. They can thoroughly inspect products across the production line. Together, these technologies give AI-based smart quality inspection systems the power to transform quality control in manufacturing. They make it faster, more reliable, and less error-prone than ever before.

The Benefits of Implementing AI in Quality Inspection

Integrating AI-Based 3rd party inspection into manufacturing brings a significant shift towards operational excellence. It enhances defect detection abilities and operational efficiency. A major advantage is remarkably improved accuracy in identifying defects. By using machine learning algorithms and computer vision, AI systems can detect anomalies with extreme precision. This reduces the margin of error to almost negligible levels. It drastically minimizes faulty products reaching the market. This protects the manufacturer’s reputation and reduces costs from recalls and customer dissatisfaction.

Using Artificial Intelligence (AI) for quality inspection in factories is a smart move. These systems work very fast. Unlike people, they don’t get tired or make mistakes. This helps production lines run smoothly without delays. Also, AI inspection doesn’t miss things like humans might. It checks every detail carefully.

When machines do the inspections, skilled workers have more time for other important tasks. They can focus on jobs that require human skills and thinking. This makes better use of people’s talents. It also makes their work more interesting and engaging. The data collected by AI systems is very valuable. It shows how the manufacturing process is going. Companies can use this information to improve their methods, reduce waste, and make higher quality products. This creates a cycle of constant improvement driven by real facts and numbers.

Overcoming Challenges and Limitations

Implementing AI-based smart quality inspection systems in manufacturing is not easy. One major challenge is getting enough high-quality data for the AI models to learn from. The better the data, the more accurate the defect detection will be. So robust data management is crucial.

Integrating AI inspection technology also requires investing money upfront – for the technology itself, training staff, and restructuring processes. This can disrupt current workflows. Careful planning is needed to minimize downtime and ensure employees support the change.

Another issue is making sure AI systems can adapt when product designs or manufacturing methods change, without needing extensive retraining. AI models need flexibility to quickly adjust to new conditions. Ongoing research aims to develop more adaptable AI for long-term effectiveness. Quality inspection with AI is growing rapidly. Advancements in machine learning will boost AI’s defect detection abilities. False positives will decrease, and detecting subtle flaws will improve.

The Future of Quality Inspection with AI

AI algorithms are progressing through machine learning and deep learning techniques. This progress will make smart inspection systems smarter. They will spot more defects accurately, with fewer false alarms. The systems will also get better at finding tiny flaws that humans might miss.

In addition to better algorithms, sensor technology is advancing too. New, high-resolution sensors will provide richer data inputs to AI systems. With better computing power and data, AI inspections will become more precise and insightful. This combination is key to realizing AI’s full inspection potential.

AI is also merging with Industry 4.0 tech like the Internet of Things (IoT) and big data. In smart factories, inspection will connect to manufacturing through AI and IoT. Real-time quality data will enable instant process tweaks. This integration will optimize quality control and efficiency on a massive scale.

Conclusion: Using AI for Smart Quality Inspection

Adding AI to quality inspection in manufacturing is a game-changer. It makes finding defects easier and faster. It also gives manufacturers deep insights into their production lines. This helps them improve their techniques and make higher quality products. As AI gets better, smart quality inspection will become even more precise and adaptable. In the future, excellence in manufacturing will be defined by insights from AI. Products will not only meet higher standards, but be made with consistency and reliability levels never seen before. Embracing AI-powered smart quality inspection is an exciting journey into new territory. It promises to bring innovation to manufacturing. For inspection companies and manufacturers, switching to these advanced systems is more than just upgrading technology. It’s a strategic move to gain a competitive edge in the rapidly changing global market. Looking ahead, the role of AI in redefining manufacturing excellence is clear. Adopting it will be a necessity for those aiming to lead in quality and efficiency.